Whether you have to operate the raising of your roller shutter by hand or using an electric switch, it may not react or show signs of weakness. This failure is one of the most annoying since you are sometimes forced to stay in the dark for an indefinite period. It can come from different origins, but fortunately, solutions more or less accessible to everyone can solve the problem.

So, without further ado, discover in this article why does your roller shutter no longer go up? How to fix the problem by yourself with detailed explanations. Then, what to do if, despite everything, your shutter no longer opens: who to contact and how to unblock or remove the shutter that does not go up while waiting for its repair.

Why does your roller shutter no longer open?

When your roller shutter no longer goes up to the top, no longer at all, or you have to help it go up, several components of the latter may be at fault. Indeed, a roller shutter consists of an apron (the set of roller shutter slats) which rolls up on a shaft present in the boot thanks to a motorization in the case of an electric shutter or thanks to a crank in the case of manual roller shutter. But then, when your roller shutter no longer opens, what more exactly can be the different failures that affect these components? :

- The strap or the crank is incorrectly positioned or faulty

- A blade is misaligned, jammed or broken

- The apron and/or its winding shaft are blocked or damaged

- The apron came out of its slide (also called rail)

- The motorization is defective. In this case, it can be its power supply, a capacitor or the motor itself

- The roller shutter switch is faulty or the remote control has run out of batteries

Si your electric roller shutter that does not roll up is controlled by a remote control, check the condition of the batteries now by replacing them with new ones.

Note that when a manual shutter no longer goes up, the failure comes in most cases from the crank, while on an electric shutter, it is very often a motor failure. But it obviously happens that other factors could be responsible for your breakdown. Fortunately, certain roller shutter behaviors can help you diagnose it. Discover then, in the next part of our article, all the checks and manipulations to try to identify the fault by yourself.

Read also: Squeaky roller shutter, what to do?

How to repair a roller shutter that no longer goes up?

When your roller shutter no longer goes up on its own, it will then be necessary check and test its various components to identify the faulty one and thus repair the fault effectively. Whether your shutter is electric or mechanical, we invite you to follow our troubleshooting guide in order. Note that some mechanical and electrical authorizations are required for most manipulations.

![]() Things to know before you start:

Things to know before you start:

- If your roller shutter that does not go up is still under warranty (2 years minimum in France and up to 10 years), call on the assistance of the manufacturer or installer of your shutter. He should send you a technician to repair your faulty electric shutter free of charge. Attention, do not carry out the manipulations described below as this may cause you to lose your rights to the guarantee!

- If you are a tenant, repairs or repair costs must be borne by your landlord. In the event of greater damage to the shutter following an intervention on your part, you may be required to pay the price of the repair.

- Risk of electric shock and irreversible damage to the shutter. If you are not competent for one or more manipulations, we strongly advise you to call on a professional. Never force the mechanism, at the risk of further damaging it. When checking the components of an electric roller shutter, it is essential to cut the electrical circuit of the latter via your control panel. You can choose to cut the electrical circuit of the room in question or of the entire dwelling. Remember to adjust the limit switches after the power cut, referring to the user manual.

Check roller shutter slats

The first check to perform when your shutter no longer rolls up concerns its slats. This is all the more so when the roller shutter motor makes noise but does not raise the apron (all the slats). Note that if your roller shutter no longer rises entirely, but it rises partially, the failure may be due to a faulty slat.

Indeed, it may be thatone or more of the blades of the apron are defective (twisted, damaged, broken, misaligned or dirty) and that they then block the winding of the electric or manual roller shutter. To diagnose this problem, all you need to do is observe the condition of the blades. Then, according to your observations and the state of the blades, find the appropriate solutions :

1 – Dirty Blades

This does not always seem obvious, and yet! It happens that blades too dirty block the winding of the roller shutter, whether electric or manual, and thus prevent it from rising. If you notice that the blades are invaded by dirt (debris, leaves, insects, stubborn dust, etc.), carry out a good cleaning.

For clean the blades of your rolling wheel, the best thing is to refer to the instructions for use. In most cases, you just need to do this:

- Dip a sponge in soapy water (preferably mild soap such as Marseille soap or black soap) mixed with a few drops of white vinegar for even more efficiency.

- Pass a blow on all the blades.

- Rinse with a sponge and water.

- Dry off the bulk of the water using a soft, lint-free cloth.

Remember to regularly clean the slats of the shutter with a suitable product or a mild product (example: Marseille soap), to prevent them from being damaged. In any case, avoid cleaning with abrasive products. A maintenance every 6 months is strongly recommended.

2 – Blades misaligned

Si blades are misaligned or moved, replace them with your hand, one by one in the center, so that they are all aligned. Indeed, if one or more slats come out of alignment, this blocks the winding axis and the roller shutter can then no longer go up.

By replacing the slats that may have come out of their axis, the apron mechanism should work again. Be careful, be delicate in your manipulations. Never force as you risk further damaging the mechanism. In case of broken blades, the only solution is to change them.

Please note: Only aprons without end caps and storm clips are affected by this problem. These are usually PVC aprons of small sizes. The recent and aluminum shutters are practically all equipped with staples or end caps which then allow them to be fixed and prevent this alignment problem. If you're not sure if your shutter has side caps or clips, it's simple. If the blades cannot be moved from side to side easily enough by your hand, then they are attached.

3- Defective blades

If your roller shutter does not go up because of a broken, bent or defective slat or slats in any way, you can choose replace them individually or replace the apron as a whole. Note that depending on the model of your shutter, it is not always easy to replace the slats individually. Sometimes it is even impossible to do so. To be sure, we advise you to contact the shutter manufacturer. If the operation is feasible, you can ask the advisor if they provide the blades in spare parts. Thus, you will be sure to have certified, qualitative and compatible parts.

In any case, even if the manufacturer does not supply the spare parts, you will need replace defective blades with identical new ones. Then you will need to dismantle the trunk (also called box), remove the apron clips to unroll the apron manually (refer to a video tutorial to do this. For example: Broken down motor: remove/remount the apron of a roller shutter). Then take the apron out of the slides (also called rails), unclip the faulty blade from the apron and slide it to the side to remove it. Then you just have to put the new blade back in its place, put the apron back on the winding axis, then reposition it correctly in the slides. Then proceed to limit switch adjustment. The manipulation is in the user manual of your model.

If the blades cannot be changed individually, you cannot obtain identical spare parts, too many blades are defective or the handling is too complicated, then you can change the entire apron. Once again, please note: depending on the make and model of your roller shutter, the curtains are not identical (size, length, mechanism, PVC or aluminum materials, etc.). Replace the old apron with one identical or compatible with the shutter mechanism.

4 – Faulty apron

Also note that over time the apron may undergo modifications affecting the opening of the shutter. If it appears to be deformed or dilated, it will also need to be replaced. In this case, avoid forcing the shutter to rise as this could also damage the winding mechanism. Once again, rreplace the old apron by an identical or compatible with the shutter mechanism.

Be careful not to force the slats or the apron at the risk of damaging your entire roller shutter.

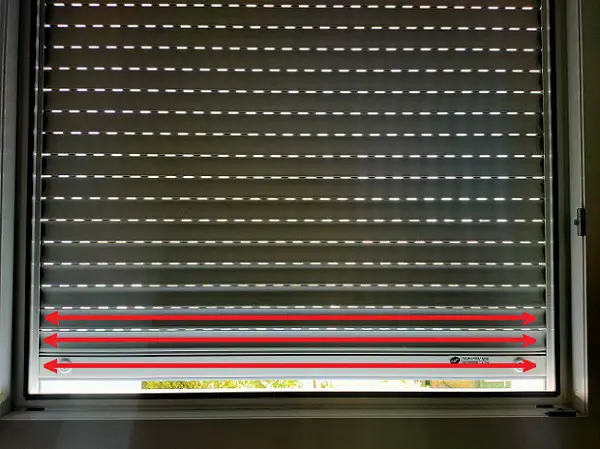

Check the slides of the shutter which no longer opens

If the blades do not appear to be the cause of the problem, it may be the roller shutter does not go up because of the slides, also called rails or slides. These can be clogged, blocked by debris (insects, dust, etc.) or damaged. It also happens very frequently that the apron derails, that is to say that it comes out of the wings through which it is supposed to slide.

If the slats seem out of alignment or dislocated from the slides of your roller shutter, you will then have to put them back in place so that the curtain can go up again. This manipulation applies to both electric roller shutters and manual roller shutters.

For clean or replace the slats in alignment with the slides, you will need to do the following:

- Open the trunk, remove the apron clips to remove the apron by hand and take it out completely (refer to a video tutorial to do this).

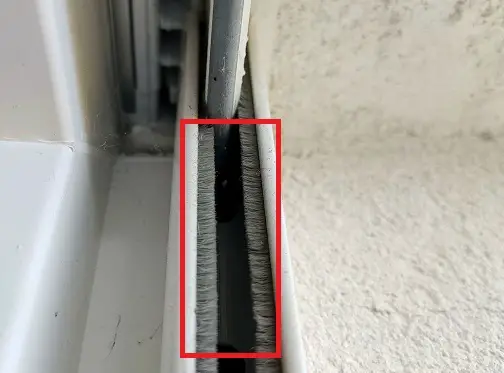

- Dust, clean and grease the slides which are often responsible for the blade misalignment problem. Use a suitable lubricating product. We recommend a silicone spray lubricant.

- Replace the apron around the winding axis and in alignment with the rails

- Then proceed to limit switch adjustment

Note that if the shutter gets stuck in a specific place on the way up, it is interesting to see if the backstage seems clogged or damaged at this level.

Be careful to carry out this operation you will need to be delicate so as not to damage the apron and the slides, but also to be vigilant so as not to injure yourself with the blades.

Check the winding mechanism in the trunk

When your electric or manual roller shutter no longer goes up, it is also possible that the winding mechanism in the trunk is faulty for several reasons.

Note that there are several winding mechanisms: winch, strap or electric. Depending on the mechanism corresponding to your shutter, adapt the checks and operations below.

In all cases, the checks and manipulations that follow will ask you toopen the trunk (also called caisson). Generally, to do this, you will need to unclip or unscrew the front or lower part of the box. The manipulation will obviously depend on your model. If the safe is built into the wall, then you will need to call on the assistance of the builder or a carpenter.

Once the subwoofer of your roller shutter that no longer rolls up is open, you'll have to check the following points :

1 – Make sure the apron clips are not loose or broken. Note that at this stage, if you hear the motor running but your electric roller shutter does not go up, the problem very often comes from the apron fasteners which have come apart. If these are detached, you just need to reattach them. If they are damaged, you will then have to replace them with an identical or compatible reference.

2 – Check that the mechanism has not come out of the winding axis or that no part or foreign body is blocking the rising of the roller shutter. Also make sure that the winding shaft has no visible damage (blows, dents, cracks, etc.).

3 – Check that the upper slat of the shutter don't be broken. The high blade is the blade attached to the winding axis. In this case, the axis can no longer drive the rest of the shutter, and if your shutter is electric, the motor then turns in a vacuum. In this case, you will have to change the entire apron.

4 – If your roller shutter that no longer goes up is equipped with a strap mechanism, check that it is not not cut or damaged and that it is correctly placed in the mechanism. You can also take the opportunity to operate the idle reel to control the ease of rotation of the system. If you notice a resistance that seems abnormal, it is possible that the support is deformed and that this prevents you from raising your roller shutter. In this case, the strap mechanism will have to be replaced.

5 – If your roller shutter that no longer opens is equipped with a winch mechanism (crank shutter only), this part may need to be replaced or you may need to lubricate it with silicone spray. It is located at the end of the drive axis. Check that the latter is not blocked ou dirty. Then, if necessary, spray a little bit of lubricant. Finally, check that it is not broken.

6 – Check that the guide tulips or guide flanges are not insufficiently lubricated or broken. First, try spraying on silicone lubricant spray if the shutter has trouble going up. If it does not go up at all, check that these parts are not broken. If so, replace them.

Remember to adjust the limit switches after replacing a component. The procedure can be found in the user guide for your shutter. It generally consists of making a sequence of manipulations on the control or directly on the electric shutter.

Check the crank of the manual roller shutter which does not go up

If your roller shutter which no longer opens is electric, this part does not concern you.

When your manual roller shutter no longer goes up, you'll have to check if the crank has not come out of the winding axis or if it just isn't broken.

To do this, open the boot and check that the crank has not come loose from the winding shaft. If so, reposition it. When you activate it, it should then again be able to turn the axis and therefore raise your shutter.

If the crank turns in a vacuum, it is possible that the winch is broken (check this at the box level), that the gimbal of the crank is broken or quite simply that the drive rod (or attack rod) for crank winch transmission may fail after repeated use. In the case of one of its failures, the crank can no longer operate the mechanism even when it is well placed in the winding axis. It will then be necessary to choose:

- disassemble the handle and check that the drive rod is correctly positioned and in good condition

- replace the crank shaft

- or replace the entire crank

Check the roller shutter switch which no longer goes up

When your roller shutter no longer opens, the problem may also come from the switch. There may be a bad contact or just be it defective with time.

If your shutter is controlled by a remote control, you will simply have to try to replace the batteries with new ones. Otherwise, on a wall switch, the tests and manipulations to test its condition are much more technical since it will be necessary to disassemble the switch, test its wires using a multimeter, then if necessary, replace it by making a connection with the connections. These manipulations must therefore be carried out by a professional in the sector or an electrician.

As an indication, for check if the switch on your roller shutter no longer works, you will need to perform a continuity test with a multimeter set to continuity mode or set to resistance (ohms) function if the device does not have this mode. The multimeter should beep or display a value close to 0 when running and no beep, 1 or OL when stopped. If the multimeter does not display anything or does not beep in the on position, this confirms its failure and therefore that your electric roller shutter does not go up. It will then have to be replaced. Attention, this manipulation is done without power!

If your switch does not work from the first uses, the technician may have made the connections incorrectly. In this case, contact the company that installed the shutters for you to come and make the connections again free of charge.

Check the motorization of the electric rolling panel

If your electric roller shutter no longer goes up without help, whether it shows signs of fatigue, or ends up not opening at all, it's a safe bet that the engine is the cause of the problem.

A simple way to find out if the motorization is the cause of the problem with your electric roller shutter raising is simply to listen to whether it is making noise or not. If the roller shutter no longer rolls up but you hear a noise when you press the switch, then the motor is working and is not the cause of the problem. On the other hand, if you do not hear no noise or a strange, unusual, jerky, or jammed noise when you flip the switch, then the motor is probably faulty. In this case, it may be a power supply problem, a worn capacitor, a deprogrammed limit switch setting, or the motor itself which has burnt out.

1 – Check motor power supply

Initially, when your shutter no longer works following a breakdown in the motorization, remember to check his diet :

- Check that there is no general power failure in your accommodation.

- Check your electrical panel to see if a circuit breaker is down. This means that it has blown due to a short circuit or voltage spike. In this case, reset it or replace the associated fuse. If it jumps when you operate the shutter, then the problem comes from a short circuit in the connectors of the latter. In this case, check that the connectors of the shutter and its motor are in good condition and well insulated. If you are not competent for the manipulations, call a professional.

2 – Adjust the limit switches

Following a power outage, or simply a bug, it may be that the limit switches are deprogrammed and that they are responsible for the fact that your roller shutter no longer opens.

In principle, the stops are programmed during assembly of the roller shutter. Then try to reset the motor (if the function exists on your model) and reprogram the limit switches. You can find the manipulation on the instructions for use corresponding to your model.

3 – Check the engine

If your electric roller shutter no longer goes up without help or at allThen the engine itself is probably at fault. The manipulations to dismantle, test and repair a roller shutter motor require very advanced electrical skills. If you do not have the necessary clearances, then call a professional.

As an indication, the motor of an electrical panel is located in the winding axis. To access it, you will have to disassemble the trunk, remove the apron, disassemble the axle and remove the motor that is inside. It will then be necessary to mechanically and electrically test the various parts of the engine.

Replace capacitor only

Note that the capacitor (cylindrical part connected to the motor) is often responsible for the failure you encounter on the motor of a roller shutter. If you have to help your roller shutter to go up, it makes an abnormal noise, it stops going up after only a few centimeters, the capacitor is probably too worn.

In addition to being more ecological, the replacement of the latter for a few tens of euros is often enough to find a motor and therefore a shutter in working order. The capacitor makes it possible, among other things, to manage the power supply to the motor and therefore to initiate its start-up. It is relatively easy to change. However, be sure to replace it with one with the same original value (expressed in micro Farad, µF). Note that a capacitor with too low a capacitance will have trouble starting your motor. Conversely, with too high a capacitance, the capacitor may burn out.

Personalized video tutorials exist on the internet for more details on testing and replacing a shutter capacitor. For example, you can refer to the following video: How to recognize a failed capacitor in a roller shutter or blind motor.

Replace motor

If the capacitor is not the cause of the fault, then you will need replace the entire motor. Count between 100 euros and 250 euros, knowing that the sale of roller shutter motors is not always accessible to individuals. Be careful to replace the defective motor with an identical and original motor. Avoid counterfeits which can be dangerous for you and your roller shutter. Once again, video tutorials exist to help you with the procedure for dismantling, reassembling and adjusting the new engine.

If, unfortunately, nothing helps and your roller shutter still not working, then you will most certainly have to contact a professional in the sector.

Roller shutter that does not go up: what to do if you cannot solve the problem?

When your shutter no longer goes up by itself or at all and you have not been able to solve the problem, you will then have to call a professional. And to avoid finding yourself in the dark while you wait for the intervention, know that there are solutions to unlock or remove the flap that does not go up.

Contact a professional to repair the broken roller shutter

First, if your roller shutter that no longer opens is still under warranty (which can range from 1 year to 10 years of warranty), call on the assistance of the manufacturer or the technician who installed it for you. In case of warranty, the repair costs will be borne by them.

Otherwise, if you no longer have the right to the guarantee, you can choose between contacting the manufacturer's assistance, the technician who installed the roller shutter or a carpenter self-employed entrepreneur.

If you are tenant and one of the roller shutters in the rental apartment you are in no longer works, then contact your landlord. If the breakdown is related to wear or a manufacturing defect, and not related to a lack of use on your part (shock, poor maintenance, etc.), then the repair must be at his expense.

Solutions to unlock or remove the roller shutter that no longer works

If your rolling steering wheel does not go up and you find yourself in the dark, solutions may help to unblock the situation while waiting for an intervention from a specialist. Warning, do not try to raise the cover manually as you risk breaking the anti-lifting locks (or apron fasteners):

Using an emergency maneuver for a motorized roller shutter

Many models of electric roller shutters are equipped with a emergency maneuver allowing you to reassemble it in the event of electrical problems or power outages. This maneuver is in fact a crank that attaches to an emergency attachment point on your roller shutter. Some brands provide the safety crank, but otherwise, you will unfortunately have to buy it for around thirty euros.

Unhook the roller shutter manually

For manual roller shutters, and some electric shutters, only one solution: unhook the apron from the winding axis which is in the trunk. Do not hesitate to consult video tutorials to help you in handling. We recommend the following video: Broken down motor: remove/remount the apron of a roller shutter.